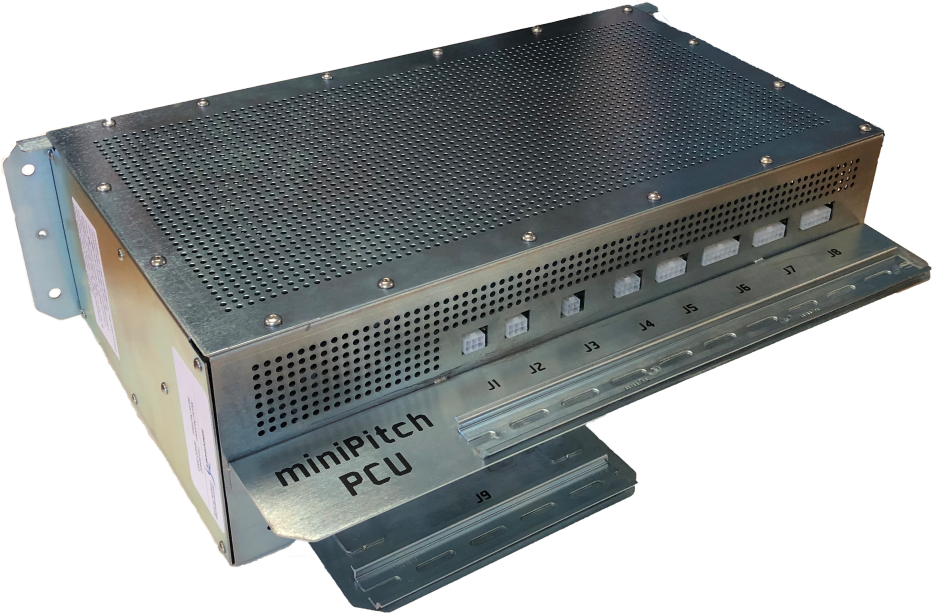

Founded in 2000, Windurance is recognized as the pioneer of servo-electric blade pitch actuator technology for utility-scale wind turbines in widespread use throughout the industry today. Turbines using full span pitch regulation deliver higher annual energy production and offer net lower cost of energy. Reduction in acoustic noise is realized, and other advantages. With shared investment from the U.S. National Renewable Energy Laboratory’s Competitiveness Improvement Project, Windurance has created the compact, low-cost servo electric blade pitch actuator for the Distributed Wind Energy turbines from 50 kW to 1500 kW scale, called miniPitch. This servo actuator package supports collective and individual pitch control strategies and offers unique turbine safety features in an advanced brushless motor control technique. Integral ultracapacitor energy storage and other special protection features provide for zero voltage ride-through (ZVRT) and high voltage protection and ride-through operation (HVRT), eliminating the need for any other backup power.

These and other features combine to make UL 6141 and UL 6142 certification of individual triune designs much easier with Windurance providing turbine-specific DFMEA and other support in conjunction with the fundamental miniPitch design properties.The miniPitch actuator design hosts a rich environment of control and condition monitoring data features. Built-in, high-order, pitch trajectory generator makes the implementation of turbine control strategies easy. This aerospace command generator constrains bale pitch motion according to the response capabilities of the blade and turbine structures. While miniPitch is essentially a maintenance-free product, pitch actuator condition and service life data are collected, binned, and stored on board the Pitch Control Unit. This historical information is a direct reflection of the turbine operational service life experience. The data can be accessed remotely to evaluate individual site conditions, and to predict turbine service maintenance schedules. With more than 23 years of experience in wind turbine subsystem designs, Windurance offers a mature pitch actuator design optimization service through the post-processing of aeroelastic models that map to dimensioning all elements of the servo actuator system. To help wind turbine OEMs evaluate the value of using pitch control, Windurance offers these services at no charge. Learn more about Windurance and its technologies here.